Understanding the Benefits of a Tube Stranding Machine in Cable Manufacturing

Release time:

2025-02-02

Understanding the Benefits of a Tube Stranding Machine in Cable Manufacturing Table of Contents 1. Introduction to Tube Stranding Machines 2. What is a Tube Stranding Machine? 3. How Tube Stranding Machines Work 4. Benefits of Using Tube Stranding Machines 4.1 Improved Productivity 4.2 Enhanced Quality 4.3 Cost Efficiency 4.

Understanding the Benefits of a Tube Stranding Machine in Cable Manufacturing

Table of Contents

- 1. Introduction to Tube Stranding Machines

- 2. What is a Tube Stranding Machine?

- 3. How Tube Stranding Machines Work

- 4. Benefits of Using Tube Stranding Machines

- 4.1 Improved Productivity

- 4.2 Enhanced Quality

- 4.3 Cost Efficiency

- 4.4 Versatility in Manufacturing

- 4.5 Reduced Waste

- 5. Applications in Cable Manufacturing

- 6. The Future of Tube Stranding Machines

- 7. Frequently Asked Questions

- 8. Conclusion

1. Introduction to Tube Stranding Machines

In the dynamic world of **cable manufacturing**, the need for precision, efficiency, and reliability has never been more critical. **Tube stranding machines** have emerged as a pivotal technology in this sector, facilitating the production of high-quality cables for various applications. By understanding the benefits of these machines, manufacturers can make informed decisions that enhance their production processes and overall competitiveness in the market.

2. What is a Tube Stranding Machine?

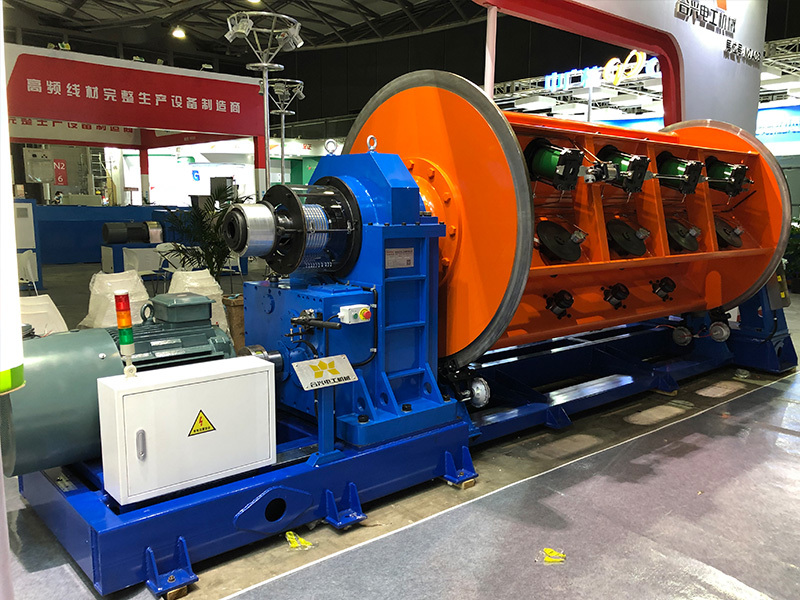

A tube stranding machine is a sophisticated piece of equipment specifically designed for the stranding of wires and cables. Unlike traditional stranding machines, which often employ a drum-based system, tube stranding machines utilize a tubular structure that allows for more efficient and flexible cable production. This design enables the simultaneous stranding of multiple wires, resulting in a more compact and organized output that meets stringent industry standards.

3. How Tube Stranding Machines Work

The operation of a tube stranding machine involves several key processes. Initially, wires are fed into a **tubular chamber**, where they are arranged in a predetermined pattern. The machine's advanced controls enable precise synchronization and tensioning of each wire, ensuring a consistent and uniform stranding process.

Once the wires are properly aligned, they are twisted together, forming a stranded cable. This method not only improves the mechanical properties of the cable but also enhances its overall electrical performance. The final product can be further processed or insulated, depending on its intended application.

4. Benefits of Using Tube Stranding Machines

Understanding the advantages of tube stranding machines is essential for manufacturers looking to optimize their cable production processes. Below are some of the key benefits:

4.1 Improved Productivity

One of the most significant benefits of tube stranding machines is their ability to enhance productivity. These machines can process multiple wires simultaneously, significantly reducing the time required for production. Furthermore, the automation features integrated into modern tube stranding machines minimize manual intervention, allowing operators to focus on other critical tasks. This results in higher throughput and improved overall efficiency in the manufacturing process.

4.2 Enhanced Quality

Quality is paramount in cable manufacturing, and tube stranding machines excel in producing cables that meet stringent quality standards. The precise control mechanisms allow for consistent stranding, which directly impacts the mechanical and electrical properties of the finished product. This results in cables that have improved durability, flexibility, and conductivity, making them suitable for various demanding applications.

4.3 Cost Efficiency

Incorporating tube stranding machines into the manufacturing process can lead to significant cost savings. By increasing productivity and reducing waste, manufacturers can lower their operational costs. Additionally, the high-quality output minimizes the likelihood of defects and returns, further enhancing cost efficiency. Over time, the initial investment in a tube stranding machine can pay for itself through these savings.

4.4 Versatility in Manufacturing

Tube stranding machines are designed to accommodate a wide range of wire sizes and materials, making them highly versatile. Whether producing low-voltage cables for residential applications or high-voltage cables for industrial use, these machines can be easily adjusted to meet specific production requirements. This adaptability allows manufacturers to respond quickly to market demands and diversify their product offerings.

4.5 Reduced Waste

Efficiency in production often translates to reduced waste, and tube stranding machines are no exception. The precise feeding and stranding mechanisms minimize material loss during the manufacturing process. Additionally, the ability to produce high-quality cables means fewer defective products, further contributing to reduced waste and environmental impact.

5. Applications in Cable Manufacturing

Tube stranding machines are utilized in various sectors within the cable manufacturing industry. Some of the most common applications include:

- **Power Cables**: Used in electrical distribution systems to transmit electricity effectively and safely.

- **Communication Cables**: Essential for telecommunication systems, ensuring high-speed data transmission.

- **Industrial Cables**: Designed for use in harsh environments where durability and reliability are paramount.

- **Automotive Cables**: Employed in vehicles for electrical wiring and connectivity, requiring high-quality standards.

As technology continues to advance, the scope of applications for tube stranding machines is expected to expand, further solidifying their role in the cable manufacturing industry.

6. The Future of Tube Stranding Machines

The future of tube stranding machines appears promising, with ongoing advancements in technology driving improvements in efficiency and performance. Manufacturers are increasingly integrating **Industry 4.0** concepts, such as IoT connectivity and data analytics, into their stranding machines. This shift will enable real-time monitoring and predictive maintenance, further enhancing productivity and reducing downtime.

Moreover, as global demand for high-quality cables continues to rise, tube stranding machines are likely to evolve to accommodate new materials and production techniques. This adaptability will ensure that manufacturers remain competitive in an ever-changing market.

7. Frequently Asked Questions

1. What is the primary function of a tube stranding machine?

The primary function of a tube stranding machine is to twist together multiple wires simultaneously, resulting in a stranded cable that is compact and organized for various applications.

2. How does a tube stranding machine improve cable quality?

By providing precise control over the stranding process, tube stranding machines ensure uniformity and consistency in cable production, enhancing the mechanical and electrical properties of the finished product.

3. What materials can be processed using tube stranding machines?

Tube stranding machines can process a wide range of materials, including copper, aluminum, and various insulation materials, making them suitable for diverse cable applications.

4. Are tube stranding machines suitable for both small and large production runs?

Yes, tube stranding machines are versatile and can be adjusted to accommodate both small and large production runs, catering to different market demands.

5. How do tube stranding machines contribute to cost savings?

By improving productivity, reducing waste, and minimizing defects, tube stranding machines help manufacturers lower their operational costs, leading to significant long-term savings.

8. Conclusion

In summary, tube stranding machines play a crucial role in modern cable manufacturing, offering numerous benefits that enhance productivity, quality, and cost efficiency. Their advanced technology and versatility make them an invaluable asset for manufacturers seeking to improve their production processes and meet the demands of a competitive market. As the industry continues to evolve, embracing innovations such as tube stranding machines will be essential for future success. By investing in this cutting-edge technology, manufacturers can ensure they remain at the forefront of the cable manufacturing industry.

TAG:

Recommend News

HEXING CABLE MACHINERY

TEL: +86-317-3601666, +86-317-3236119

FAX: +86-317-3618408

E-MAIL: china@hbhxdg.cn

E-MAIL: hbhxdg@gmail.com

WEB: http://www.hbhxdg.cn

ADD: Baoantun Industrial Zone, Hejian City, Hebei Province